EMPowered Heat

for

Heavy Oil

$30M

Commercial- scale pilot project

7 Months

Consecutive EMPowered Heating

RF XL v1.5

Demonstrated unprecedented performance of any RF heating system

$5M

Funding required to complete RF XL v1.5

Lowest Cost

Lower Capital Cost

50%

Utilizing Acceleware’s RF XL technology in place of SAGD is estimated to reduce the capital costs of oil sands and heavy oil production by over 50% on both a capital intensity (dollar per flowing barrel) and a total capital investment basis.

With minimal surface facility requirements and the mobility of the CTI, RF XL can be deployed at a single well or a single pad, allowing operators to profitably scale one well (or pad) at a time and relocate the system multiple times to optimize productivity and returns. The reduced size, scale and ability to redeploy the RF XL system deliver faster return on investment and higher profitability.

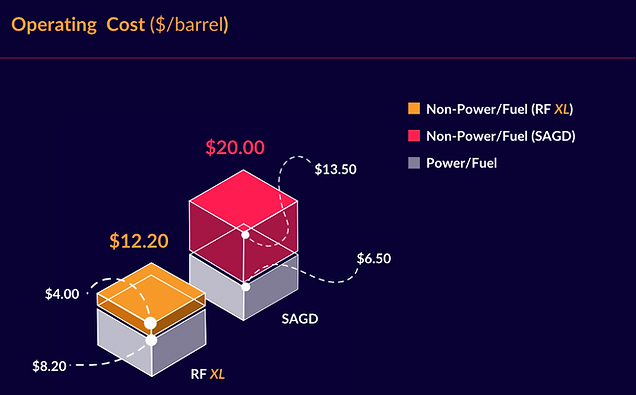

Lower Operating Cost

40%

RF XL operating cost efficiencies are driven down by an estimated 40% by a combination of decreased energy, labour and service costs. RF XL requires no ticketed steam engineers, no steam based pressure vessels, and reduced pressure vessel compliance work.

The simplified surface operations of an RF XL deployment would require fewer staff to operate, have lower maintenance and workover needs, and require less water processing and disposal. RF XL is remotely monitored and managed, so staff are only dispatched as needed for maintenance or repairs.

RF XL Commercial-Scale Pilot

Acceleware's EMPowered Heat could yield massive environmental benefits for combustion intensive industrial processes, including cleaner thermal heavy oil and bitumen production via RF XL.

Construction of a commercial-scale RF XL pilot was started in August, 2021 at Marwayne, Alberta. The CAD $30 million pilot saw seven consecutive months of EM power injection into the transmission lines, proving out the core heating technology and the Clean Tech Inverter (CTI). The pilot is currently on pause while plans are made for upgrade of downhole components to improve performance and

longevity.

The commercial-scale pilot is intended to demonstrate RF XL’s heating capabilities, alongside immediate and sustainable environmental, economic and social benefits. These include ~40% operating and capital cost reductions, no external water use requirements, near-zero GHG emissions through direct or indirect use of renewable power, a significant reduction in surface disturbance and no requirements for the addition of solvents.

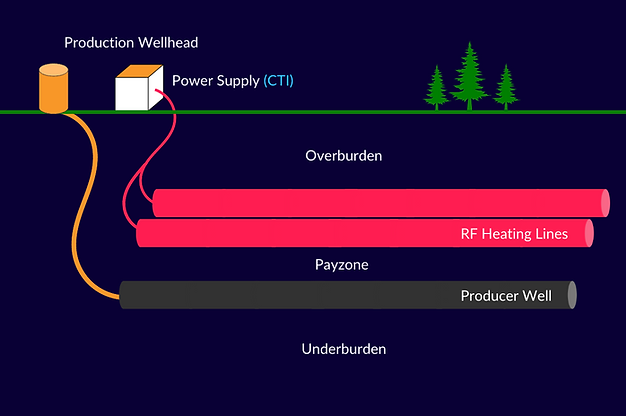

How RF XL Works

RF XL uses EM energy to generate heat, which converts the water already existing within the oil sands reservoir to steam, mobilizing the bitumen and allowing it to flow to the producing well.

Acceleware's RF XL process, coupled with new software advancements, involves the drilling of two RF heating lines into the target zone and their connection to a surface power supply.

RF XL eliminates the need for water source wells, water treatment equipment, and steam generators, as well as the requirement for costly chemicals or solvents.

Deeper Dive Resource:

RF XL technologies could enable production from a wide range of untapped geologies and reservoir formations, including:

Very deep or very thin reservoirs

Cracked or fractured rock

Shallow reservoirs

Developed reservoirs with up to 90% of the oil still in the ground